World-class Inline Sputter System | SELCOS

SELCOS Co., Ltd. has grown into a world-class company that will try unceasingly to be modest, trustworthy, and passionate to its customers all over the world.

SELCOS is well recognized for its operational

excellence of sputtering and coating-deposition process based on its

proprietary high-vacuum thin-film technology and Nano-technology that have been cultivated

since its establishment in 2007. Its cutting-edge technology and system are

specialized for depositing industrial thin film and for the display sputtering

system as well as the large vacuum area distribution system. Its Nano-thin film

coating process is suitable for the product development services and the alloy

sputtering target. inline sputtering system

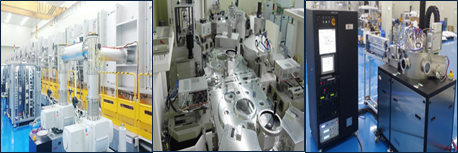

SELCOS Inline Sputter is a fully automated system and its various technologies ensure stable quality and provide expandability. It offers high mobility and maximizes productivity. These applications are applicable to various thin film (Metal, Oxide, TCO) processes, various products (Plastic, Glass, etc.), and various shapes (Deco, Tool, Special model).

The Inline Sputter specification

configuration is Loading, Pre-treatment,

Deposition, Buffer, and Unloading. The Tact time is 3 min, Cathode type is Planar or

Cylindrical Magnetron cathode, Target is

Metal, Oxide, or TCO. Depositing

Industrial Thin-Film Evaporator

This sputtering system can be used to produce thin films of material on various substrates. The Inline PVD sputtering system is one in which substrates pass linearly beneath one or more sputter cathodes to acquire the thin-film coating. Normally the substrates are loaded onto a carrier or pallet in order to facilitate this motion, and some smaller systems handle just one pallet per batch run. Larger systems may have the capability of handling multiple pallets through the use of end station pallet handlers that send and receive one pallet after another in a continuing convoy passing through the transport sub-system that enables the tip of each one to follow behind the tail of the prior one. The most common, and least complex, configuration is to have the pallets and cathodes horizontal with cathodes on top and substrates on the bottom in a sputter-down orientation.

Comments

Post a Comment