Fully automated Industrial Sputtering System | SELCOS

SELCOS

Co., Ltd. was established in 2007. Based on its high vacuum thin film

process technology and Nano-technology,

SELCOS has grown into a world class company for sputtering deposition and coating

deposition. SELCOS’s corporate vision is to become a modest, trustworthy and

passionate company for customers all over the world as a sputtering deposition system supplier. SELCOS’s cutting edge technology and systems are

specialized for depositing industrial thin film and display sputtering system as well as large vacuum area

distribution system.

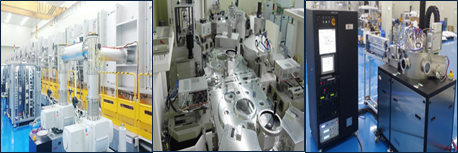

SELCOS Sputter

Deposition System

SELCOS operates three methods in sputtering system. Those are Inline

sputtering, Cluster sputtering and Batch sputtering system.

In the SELCOS Inline sputtering system, the process is fully automated to ensure stable quality and provides a wide

range of expandability by its various applicable technologies. Its high

mobility maximizes the productivity. It is widely used for the various thin

film processes such as metal, oxide and TCO. Also it is applicable to various products of

plastic, glass, etc.

In the SELCOS Cluster sputtering system, the mechanism and technology of the deposition system are highly integrated,

so that this system can be much suitable for the research and development

system and an automated production line. Thanks to such advantages, it is

widely used for the various thin film processes such as metal, oxide and TCO.

Also it is applicable to highly integrated semiconductor and electronic

component substrate processes. And, essentially, it is applicable to thin-film

solar cell manufacturing processes.

In the SELCOS Batch sputtering system, the system consists of various thin film deposition systems. So it is

much better suited for the research and development work. The main applications

of SELCOS Batch sputter are integrated optical devices, hardness coating and

electronic components.

Along with the sputtering system, SELCOS is implementing OLED Evaporation System to produce a

highly efficiency OLED panels. This system consists of three methods of systems. Those are Cluster System,

Inline System and Research and Development System. SELCOS is specialized

for organic

and inorganic deposition system for OLED panel and material development. The long service-life OLED Panels

are done by SELCOS’s evaporation and encapsulation process in an ultra-high vacuum area

by using an OLED Evaporation System.

Click here to contact

us.

View more: SELCOS World class Sputtering System

Comments

Post a Comment