High-vacuum Thin-film process Technology | SELCOS

![]() SELCOS Co., Ltd. has grown into

world-class sputtering and coating deposition company based on High-vacuum thin-film process

technology and Nano technology since its establishment in 2007.

SELCOS Co., Ltd. has grown into

world-class sputtering and coating deposition company based on High-vacuum thin-film process

technology and Nano technology since its establishment in 2007.

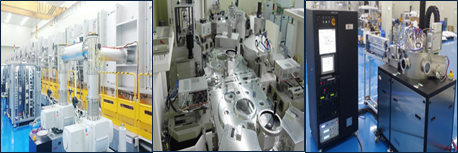

Its cutting-edge technology and system are

specialized for depositing industrial thin film and display sputtering system

as well as large vacuum area distribution system. Its Nano-thin film coating

process is suitable for the development services and alloy sputtering target.

SELCOS will try unceasingly to be a modest, trustworthy,

and passionate company to its customers over the world.

SELCOS product line-ups

ü

Premium Metallic Coating

ü

Sputtering System

ü

OLED Evaporation System

ü

Nano-thin film coating products

ü

Vacuum Parts and Alloy Targets for Sputtering

Premium Metallic Coating:

A special coating

technology that applies various colors and metallic textures to plastic, glass,

and metallic materials using the Nano thin-film sputtering technology. It is an

eco-friendly and low-cost coating technology that replaces the existing coating

and painting process. sputter deposition

system

Sputtering System Product:

Inline Sputter is Fully

Automated System. Its various technology ensures stable quality and provides

Expandability. And it

offers high mobility and maximizes the productivity.

Cluster Sputter is suitable

for automated production lines and R&D systems. Ans it provides highly integrated

technology and mechanisms.

Batch Sputter is suitable

system for R&D due to various thin-film deposition systems available.

OLED Evaporation System Product:

Cluster System is OLED Panel and material

development system. It enables efficient and long-life panel production through

deposition/encapsulation in ultra-high vacuum. Its high efficiency and long-

life property results from the proper cleaning and removing out-gassing methods.

Inline System is highly productive inline

system that moves the substrate during the deposition process and specially optimized

for OLED lighting panel production.

![]() R&D System is suitable for OLED Panel R&D system and Cost-efficient organic or

inorganic deposition to the encapsulation process. inline sputter system

supplier

R&D System is suitable for OLED Panel R&D system and Cost-efficient organic or

inorganic deposition to the encapsulation process. inline sputter system

supplier

Nano-thin film coating products:

Nano-thin film

deposition solution can be provided to customers for development, production,

and even market creation. Thin-film material design and process according to

needs via simulations and Provide an efficient and optimized layout and equipment

system for the benefit of the customers.

Vacuum Parts and Alloy Targets for Sputtering:

Self-made alloy

targets for efficient and reliable cathode sputtering and supply

organic or inorganic deposition sources and related components.

Comments

Post a Comment