Sputtering Machine System Supplier | SELCOS

SELCOS Co., Ltd. has grown into a world-class company that will try unceasingly to be a modest, trustworthy, and passionate to its customers all over the world.

SELCOS is well recognized for its operational excellence of sputtering

and coating-deposition process based on its proprietary high-vacuum thin-film

technology and Nano-technology that is cultivated since its establishment in

2007. Its cutting-edge technology and system are specialized for depositing

industrial thin film and for the display sputtering system as well as the large

vacuum area distribution system. Its Nano-thin film coating process is suitable

for the product development services and the alloy sputtering target. vacuum

deposition machine supplier

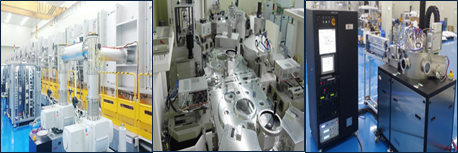

SELCOS sputtering system of Inline Sputter, Cluster Sputter

and Batch Sputter

Inline Sputter is

a fully automated system. Its various technologies ensure stable quality and

provide wide range of expandability. And it offers high mobility and maximizes

the productivity. Inline Sputter applications are applicable to various thin

films process (Metal, Oxide, and TCO), and also applicable to various products

(Plastic, Glass), and applicable to various shapes (Deco, Tool, Special model).

Cluster Sputter

is suitable for automated production lines and R&D systems. And it provides

highly integrated technology and mechanisms. Cluster Sputter applications are applicable

to various thin film process (metal, oxides, TCO), and applicable to highly

integrated semiconductor and electronic component substrate processes, and also

applicable to thin-film solar cell manufacturing processes.

Batch Sputter is

a suitable system for R&D due to various thin-film deposition systems

available. Batch Sputter applications are integrated optical devices, electronic

components and Hardness Coating. eco friendly coating

system

Specifications of

Inline Sputter

ü

Configuration: Loading, Pre-treatment,

Deposition, Buffer, Unloading

ü

Tact time: 3 min

ü

Cathode: Planar or Cylindrical Magnetron cathode

ü

Target: Metal, Oxide, TCO

Specifications of

Cluster Sputter

ü

Configuration: Loading, Transfer, Pre-treatment,

Deposition(PVD, CVD)

ü

Transfer: Hi-vacuum automatic robot

ü

Cathode: Planar or Round Magnetron cathode

ü

Target: Metal, Oxide, TCO

Specifications of

Batch Sputter

ü

Configuration: Pre-treatment, Deposition

ü

Features: Drum type, Dual-side deposition

ü

Cathode: Planar Magnetron cathode

ü

Target: Metal, Oxide, TCO

Comments

Post a Comment