World class Metallic Coating and Sputtering Deposition Company | SELCOS

SELCOS

Co., Ltd. was established in 2007. Based on its high vacuum thin film

process technology and Nano-technology,

SELCOS has grown into a world class company for coating deposition and

sputtering deposition. SELCOS’s corporate vision is to become a modest,

trustworthy and passionate company for customers all over the world as a vacuum

deposition machine supplier.

SELCOS’s

cutting edge technology and systems are specialized for depositing industrial

thin film and display sputtering system as well as large vacuum area

distribution system.

And SELCOS

is well known for its flagship coating technology for

coating deposition. It can apply

various colors and metallic textures to

plastic, glass and metallic materials.

SELCOS Premium Metallic Coating:

SELCOS is the world class company in

the metallic coating technology.

Its premium metallic coating is based on Eco-friendly

coating system with no water wastage and no toxic

gases that substantially can replace the electroplating

process. Compared to electroplating, SELCOS metallic coating provides great

advantages of no toxicity, no waste water, no harm to human body, and clean

working environment.

In addition, metallic coating lines that SELCOS owns and operates are fully

automated systems with Tact time less than 3 minutes so that the coating cost

can be reduced by 70 % compared to electroplating. SELCOS metallic coating

process can apply the various premium and high quality colors and metallic

textures to a many kinds of products regardless of base materials such as

plastic, die cast, iron and so on. Thanks to this distinctive excellence,

SELCOS metallic coating is widely used in home appliance and automobile

industries.

SELCOS Sputter

Deposition System:

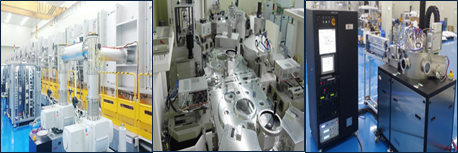

SELCOS operates three systems in sputtering system. Those are Inline

sputtering, Cluster sputtering and Batch sputtering system. sputtering system

manufacturers

In the Inline sputtering system, the process is a fully automated to ensure

stable quality and provides a wide range of expandability. The maximum

productivity is achieved by its high mobility.

In the Cluster sputtering, the deposition system’s mechanism and technology

are highly integrated. This type is much suitable for the research and

development system and automated production line. In the batch sputtering, the

system consists of various thin film deposition systems. So it is much better

suited for the research and development. The main applications of batch sputter

are in integrated optical devices, hardness coating and electronic components. cluster

sputter supplier

Click here to contact

us.

View more: SELCOS World class Coating Deposition

Comments

Post a Comment